In the first instance the plasma treating the plastic cleans away volatile organic compounds that otherwise impede bonding painting and gluing.

Plasma surface treatment of plastics to enhance adhesion.

Manufacturers integrate in line plasma treatment equipment to enhance adhesion on plastics composites metals glass surfaces.

Plasma treaters produce plasma surface treatment to promote the adhesion of inks adhesives coatings sealants paints.

Plasma surface treatment can help you enhance adhesion at a good value and with excellent results but the process remains a mystery to many designers.

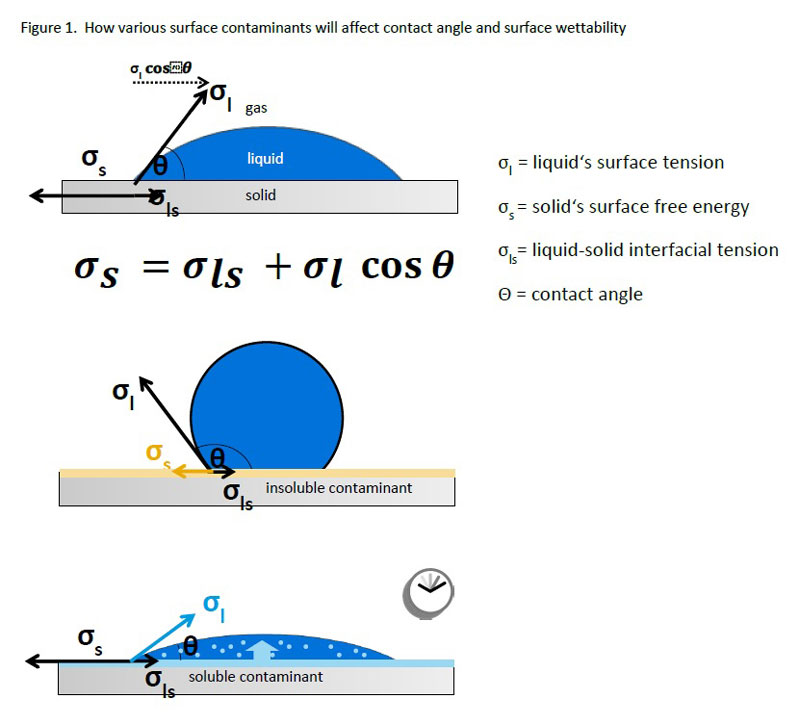

Plasma pretreatment cleans surfaces by removing contaminants.

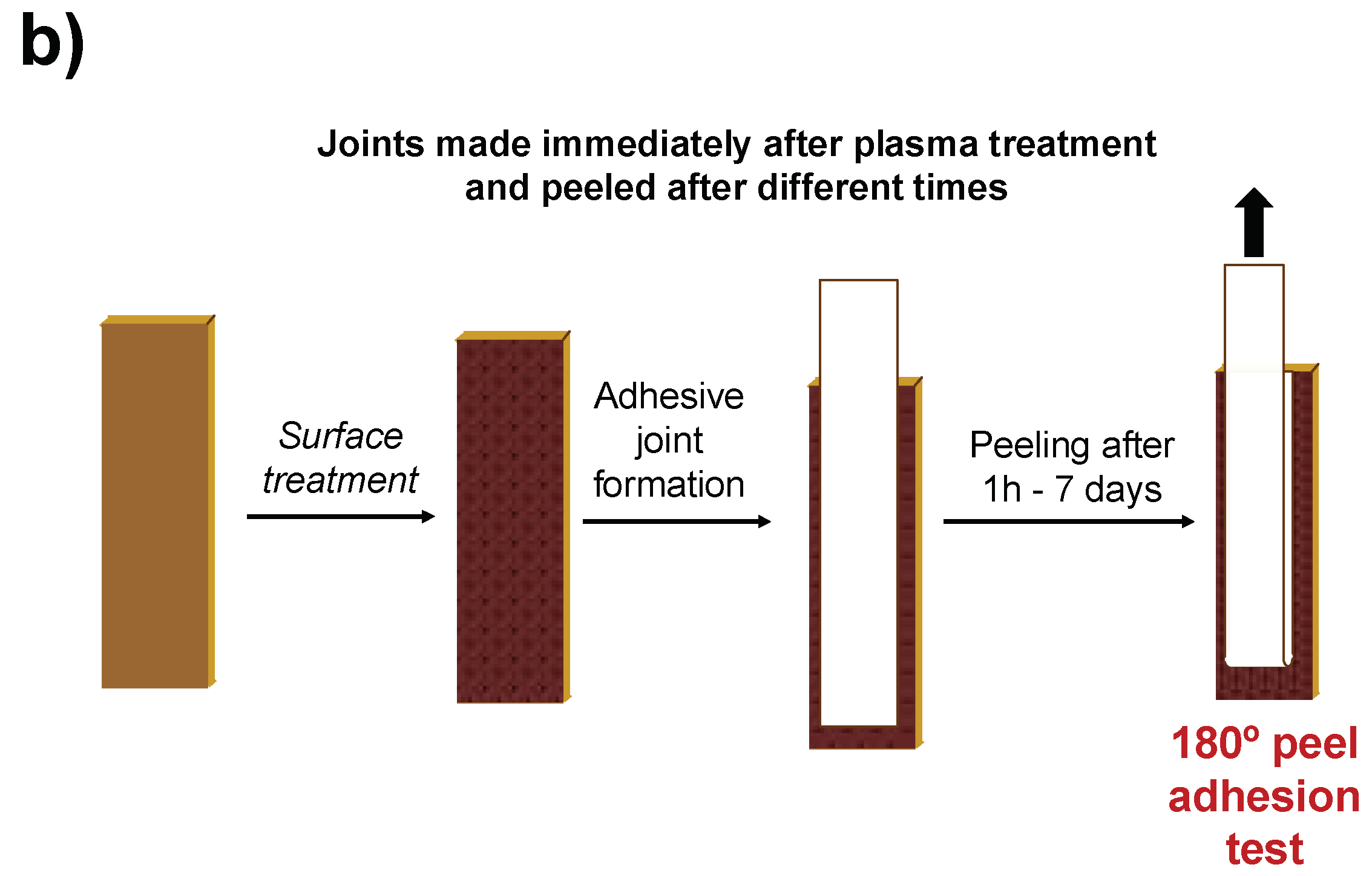

Plasma treatment of plastics to improve adhesion is a two fold surface activation and cleaning process.

Corona treaters plasma treaters and flame treaters improve the adhesion of plastics.

Improving adhesion and corona treatment for plastics.

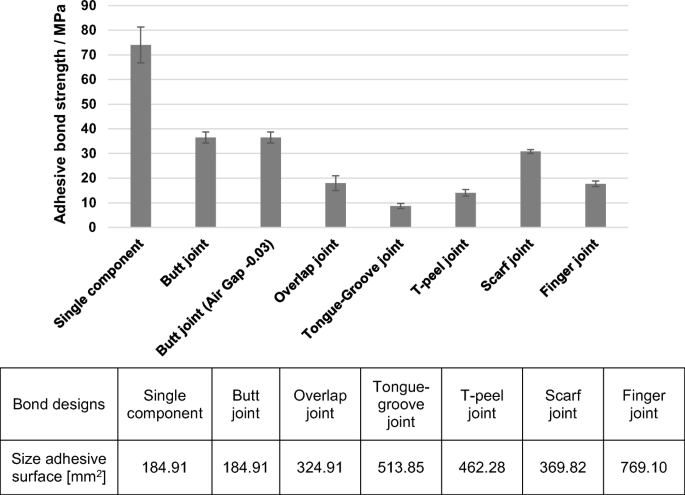

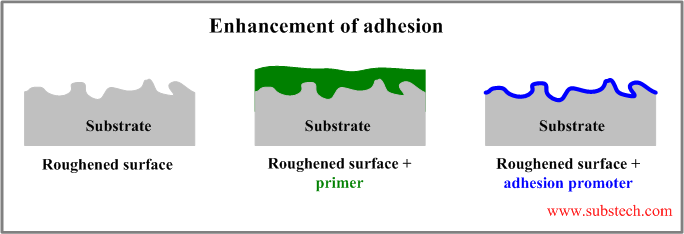

The most commonly used method for increasing adhesion to plastic is surface preparation treatment.

Plasma surface treatment of plastics to enhance adhesion s l.

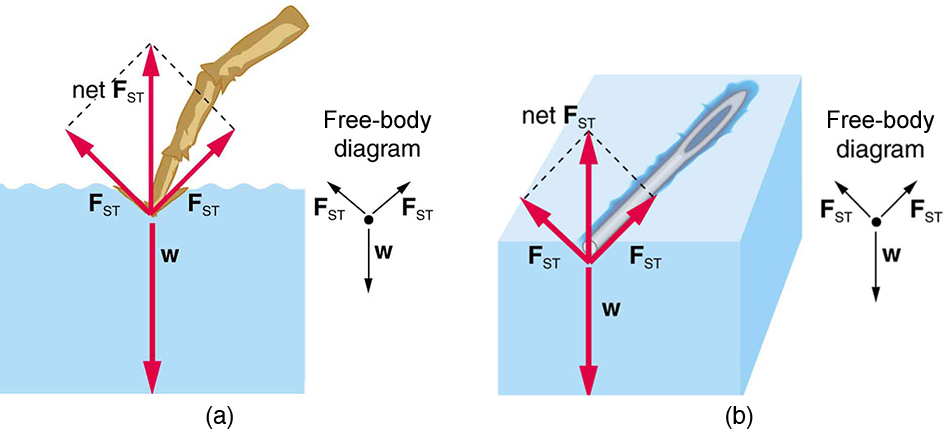

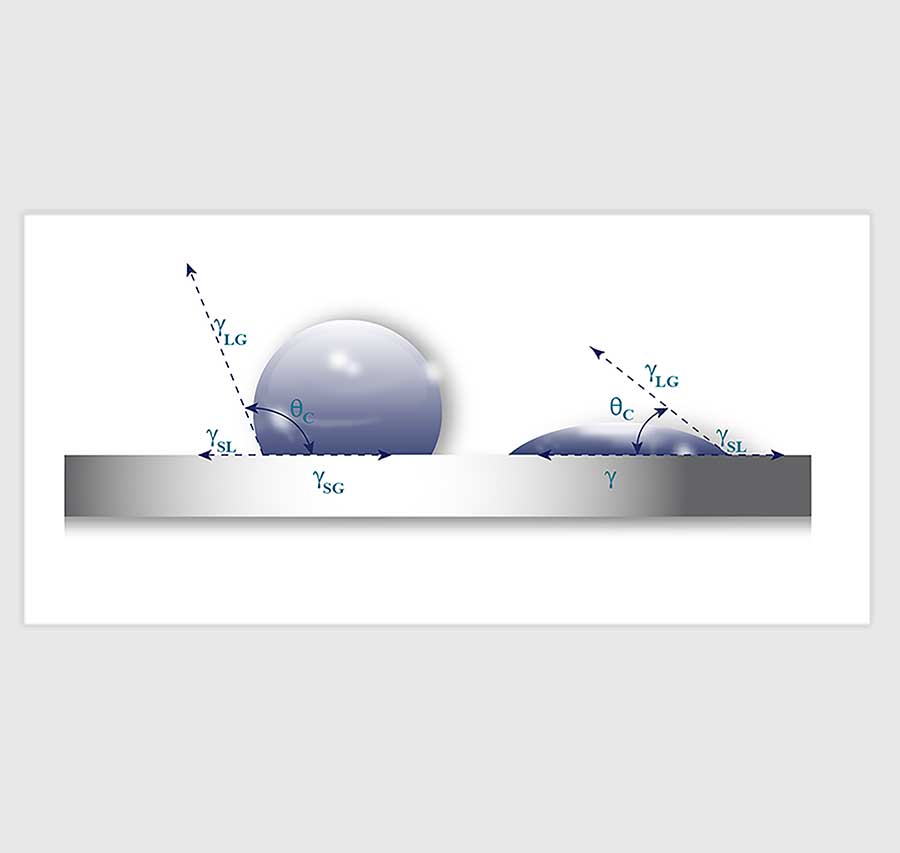

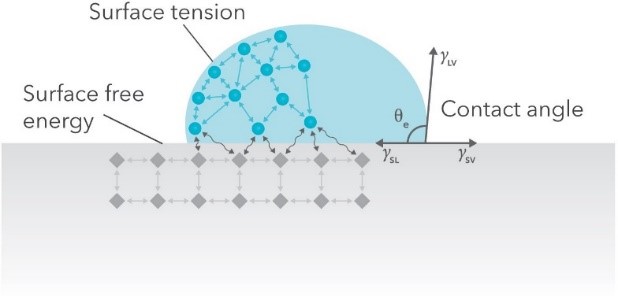

Generally a substrate s surface energy should range at least 5 mn m dyn cm above the surface tension of the adhesive paint coating or ink to be used on the surface.

The process also etches surfaces creating more bonding sites to facilitate stronger bonds and air plasma s ability to functionalize surfaces activates their receptiveness to adhering with.

The latter characteristic of plasma is being exploited for a variety of industrial applications for example as a pre treatment to increase the wettability and adhesion of coatings to plastic.

Surface preparation can be anything from plasma treatment to.

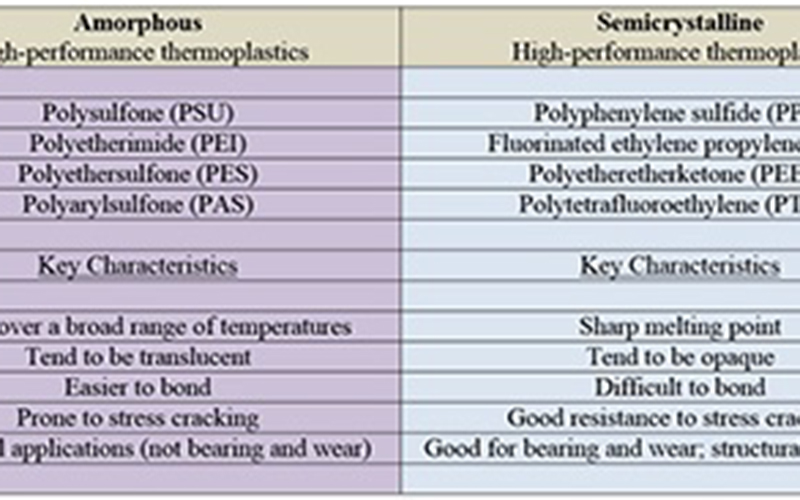

Generally plastics have chemically inert and nonporous surfaces with low surface tensions.

Manufacturers rely on in line atmospheric plasma treatment to improve bonding of adhesives on plastics metals composites and glass surfaces.

This will allow for improved wetting of the surface by the primer coating.

Polyethylene and polypropylene for example have very low surface energy.

Ideally a surface to be bonded should be dust free wettable i e.

This makes them nonreceptive to bonding with inks adhesives coatings and other substrates.

Let s take a look behind the curtain to learn why plasma cleaning is often recommended.

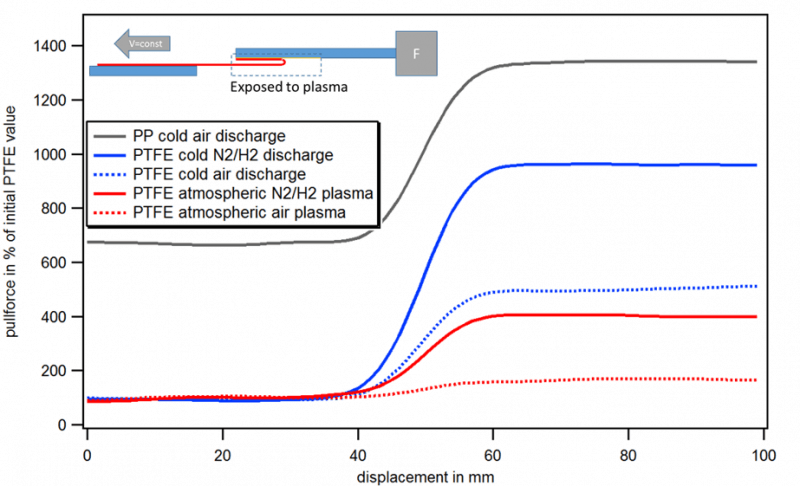

To improve the adhesion a plasma pre treatment 5 min n 2 plasma of the pc is first carried out to clean activate and cross link the polymer surface.

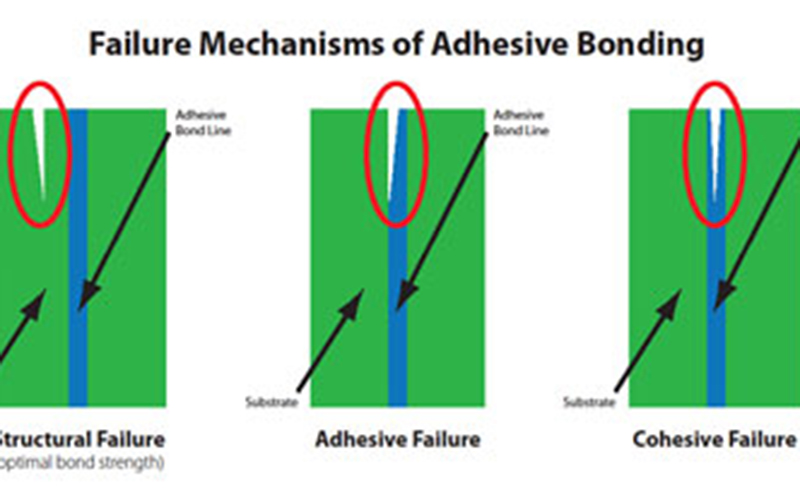

Rose plasma science usa adhesion whether the bonding of polymers or the adhesion of coatings to polymer surfaces is a recurring and difficult problem throughout the plastics industry.

.jpg)